[ad_1]

If you’ve been vaccinated for COVID-19, likelihood is fairly excessive that you simply’re benefiting from a product made by BioNTech. The German biotech firm, co-founded by a husband-and-wife group of scientists, developed the vaccine that turned not solely the primary to earn authorization within the U.S. for COVID-19 in December but in addition the primary ever based mostly on a brand new expertise involving the genetic materials mRNA.

In interviews in December and March, co-founders Ugur Sahin and Ozlem Tureci spoke about their whirlwind yr and their partnership with U.S. pharmaceutical firm Pfizer to check and manufacture the vaccine. Over three days in late March, additionally they opened up their new manufacturing plant to TIME for the primary step-by-step take a look at how their lifesaving, and doubtlessly pandemic-ending, vaccine is made.

The brand new BioNTech manufacturing facility is in a wooded valley in Marburg. Technicians working in one of many prep labs typically spot deer roaming within the close by forest.

Luca Locatelli for TIME

The equipment that acts as the center of the vaccine-manufacturing facility, regulating the movement of gasoline, water, electrical energy, wastewater and extra all through the constructing in Marburg, the place 400 staff working across the clock produce a number of million doses of the vaccine every week.

Luca Locatelli for TIME

As High quality Management Lab Supervisor, Witali Schmidt oversees the testing of all uncooked supplies coming in, in addition to the completed product going out. “The product produced right here goes into the human physique,” he says. “So it is crucial that the standard is ideal, that the individual solely will get the vaccine and nothing apart from that.”

Luca Locatelli for TIME

When Sahin learn a scientific paper in late January 2020 describing the primary recognized circumstances of COVID-19 in Wuhan, China, “it was very clear to me that this was not an area outbreak anymore,” he says. “And more than likely the virus had already unfold worldwide.”

He knew there was no time to waste. However BioNTech, based mostly in Mainz, was then primarily a cancer-vaccine firm; after greater than a decade of analysis and improvement, the corporate had examined its mRNA-based most cancers vaccines in about 400 individuals, with encouraging outcomes. They had been simply exploring the potential of creating vaccines in opposition to infectious ailments–particularly an mRNA-based vaccine in opposition to flu–when COVID-19 hit.

To maintain it protected within the physique, the mRNA is encased in a bubble of lipids by a course of that makes use of pure, pressurized ethanol. As a result of ethanol is very explosive, technicians should put on particular static-free boots.

Luca Locatelli for TIME

Operations on the Marburg manufacturing website by no means cease, not even at night time.

Luca Locatelli for TIME

Sylvia Groeb works within the early phases of the method, encoding the mRNA that teaches human cells set off the antibody response wanted to fight the virus.

Luca Locatelli for TIME

“[Ugur] satisfied all of us, together with our board, colleagues and scientific groups, that this was now our calling and we’ve to comply with this mission,” says Tureci. At an emergency assembly, Sahin urged a 40-member group to “transfer with the pace of sunshine” towards the corporate’s new purpose of growing a COVID-19 vaccine. The group, which grew to greater than 200, labored nights and thru holidays on Mission Lightspeed, and after a number of weeks had produced 20 candidates. An unprecedented 4 confirmed promise in neutralizing the virus. “There was a transparent message that this must be the precedence,” says Andreas Kuhn, senior vice chairman of RNA biochemistry and manufacturing at BioNTech. “No matter you’re doing proper now, type of overlook about it as a result of that is an important factor now.”

With so little recognized concerning the new virus, the group turned to what was recognized about two associated coronaviruses: SARS and MERS. Quickly it had a 50,000-step course of for constructing an mRNA vaccine in opposition to the brand new coronavirus, SARS-CoV-2.

Earlier than pivoting to the COVID-19 vaccine, BioNTech was largely centered on utilizing the brand new mRNA expertise to develop most cancers vaccines. “What the success of the coronavirus vaccine has now proven is that mRNA is mostly a confirmed expertise for infectious ailments,” says Andreas Kuhn, senior vice chairman of RNA biochemistry and manufacturing at BioNTech. “We have not forgotten concerning the most cancers sufferers—the most cancers applications are nonetheless operating as a lot because it’s attainable beneath the present circumstances. We’ll after all return.” Kuhn was lately vaccinated. “It was the primary time that I bought a vaccine, or any type of remedy, the place I used to be truly concerned in making it,” he provides. “In order that was actually particular.”

Luca Locatelli for TIME

It begins in a 50-L stainless-steel tank that extra carefully resembles a beer keg than what you may think to be a part of a lifesaving bioreactor. Inside are fragments of mRNA coding for the SARS-CoV-2 spike protein, the Achilles’ heel of the virus that the vaccine will exploit. Your complete manufacturing course of occurs in a hermetically sealed system, with merchandise from every stage transported to the following by way of a community of clear plastic tubing.

Even so, simply to be secure, technicians routinely take a look at the air within the manufacturing rooms for any extraneous micro organism or pathogens, and people working with the vaccine frequently faucet every gloved finger onto petri dishes stuffed with agar that may tradition for any stray microbes which may have made their approach into the power.

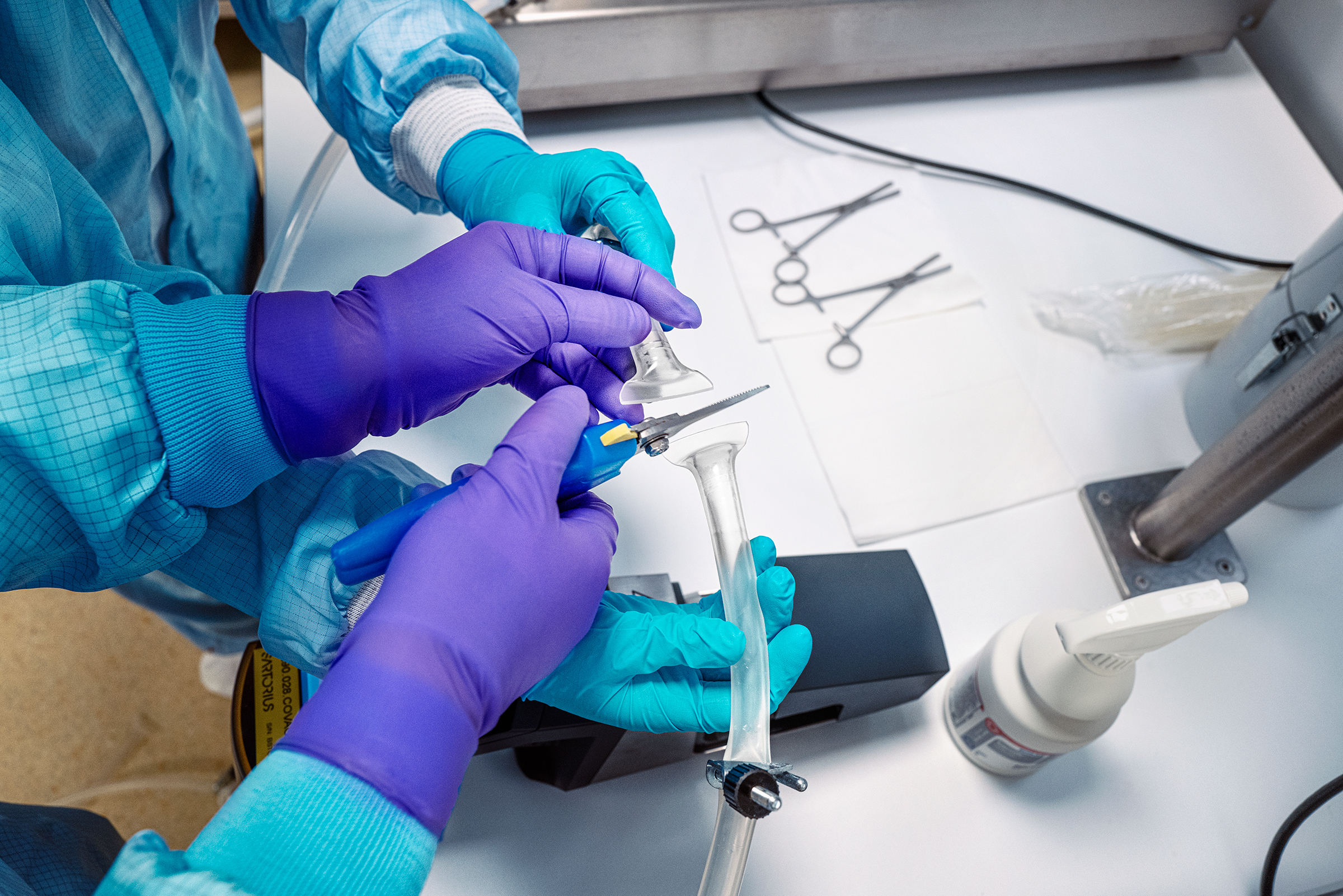

From begin to end, your entire manufacturing course of flows by hermetically sealed plastic tubing. After the vaccine is pumped into bulk packaging, the tubes are sealed, then lower, to complete the method.

Luca Locatelli for TIME

Lab technician Nabil Jajila is accountable for shifting the baggage of completed vaccines in bulk to the pallets that may finally be shipped to a different facility for placing into vials.

Luca Locatelli for TIME

Manufacturing the vaccine requires giant quantities of uncooked materials, technical gear and sterile provides. Most of it’s saved on-site in Marburg—the place warehouse operator Tolga Dik is proven—and delivered to the labs on an as-needed foundation.

Luca Locatelli for TIME

As a result of mRNA is comparatively unstable, it wouldn’t survive in its uncooked kind within the human physique. With a view to preserve the mRNA protected, it’s encased in a fatty bubble utilizing pressurized ethanol–a extremely flammable substance. The method occurs in certainly one of six 50-L tanks, every in its personal sealed-off room. The few individuals licensed to enterprise out and in of the rooms placed on particular static-free footwear to keep away from producing an unintentional friction spark that would set off an explosion. 5 of the tanks are named for group members who had been instrumental in growing the method, and the sixth is called Margaret, after the U.Ok. grandmother who was the primary individual to obtain the vaccine.

As soon as the ethanol has finished its job of making the mRNA-containing bubbles, it’s filtered out. The result’s then filtered a number of occasions extra, finally ending up as a milky resolution that fills 10-L plastic baggage. That liquid is shunted to the so-called fill-and-finish part, the place it’s purified in tanks after which squirted into sterile vials–every containing as much as six doses–which might be shipped to clinics world wide.

![Lukas Knof, manufacturing engineer at the fill-and-finish facility operated by Baxter International in Halle. "It makes me very proud to work on this product, to help the whole world," Knof says. "My first day [working with the BioNTech vaccine], I was really nervous because I had the feeling that the whole world was watching. It was a big day. For Baxter, and for me." Lukas Knof, manufacturing engineer at the fill-and-finish facility operated by Baxter International in Halle. It makes me very proud to work on this product, to help the whole world, Knof says. My first day [working with the BioNTech vaccine], I was really nervous because I had the feeling that the whole world was watching. It was a big day. For Baxter, and for me.](https://api.time.com/wp-content/uploads/2021/04/luca-locatelli-biontech-baxter-germany-covid-13.jpg)

Lukas Knof, manufacturing engineer on the fill-and-finish facility operated by Baxter Worldwide in Halle. “It makes me very proud to work on this product, to assist the entire world,” Knof says. “My first day [working with the BioNTech vaccine], I used to be actually nervous as a result of I had the sensation that the entire world was watching. It was an enormous day. For Baxter, and for me.”

Luca Locatelli for TIME

On the fill-and-finish facility operated by Baxter in Halle, 120 miles north of Marburg, technicians monitor the washing and sterilization of the vials earlier than they’re stuffed with vaccine, then stoppered and sealed.

Luca Locatelli for TIME

On the Baxter facility in Halle, 220 vials may be stuffed and capped each minute. Earlier than they’re labeled, the stuffed vials undergo one last inspection.

Luca Locatelli for TIME

BioNTech at present produces eight million doses of its vaccine each three to seven days on the new Marburg facility that the corporate bought from Novartis final fall. (Many lab technicians, most of whom transferred to BioNTech, nonetheless put on their previous lab coats with the Novartis brand, as there hasn’t been time to order new ones.) In the end, the plant will churn out 1 billion doses a yr, and BioNTech is working with Pfizer, which oversaw the ultimate human testing that resulted within the vaccine’s authorization within the U.Ok., the U.S. and elsewhere, to ramp up manufacturing to provide the two.5 billion doses it dedicated to offering the world in 2021.

Each firms are fast to level out that their work just isn’t finished. Sahin and his group are additionally keeping track of new variants of the virus beginning to take maintain world wide, and have already developed one other vaccine to focus on these viral variations, and so they plan to start out testing it quickly.

As soon as bottled, the Pfizer-BioNTech vaccine is saved at -82°C (-116°F) at a filling and labeling facility in Halle.

Luca Locatelli for TIME

With the success of the COVID-19 mRNA vaccine, Sahin and Tureci see mRNA expertise as taking part in a extra dominant function in treating different ailments as properly, and are making ready to select up the work on flu and most cancers vaccines that was interrupted by the pandemic. For now, the group is rightfully pleased with what it’s completed in a really busy yr.

“It is a once-in-a-lifetime venture,” says Alexander Muik, director of immunomodulators on the firm, who was concerned within the early phases of growing the vaccine. “Who can say that they’re a part of the answer for a pandemic? Only some individuals can say that.”

With reporting by Julia Zorthian/New York

This seems within the April 26, 2021 challenge of TIME.

[ad_2]

Discussion about this post